News in brief

Flair Suite™: supporting environmental and industrial gas monitoring

Today, air quality is an issue of major concern when it comes to public health. To protect it, it is necessary to reduce emissions but also monitor global chemical changes taking place in the atmosphere. From the economic and safety points of view, it is also important to monitor industrial gas emissions. It was to tackle these different aspects that IFPEN’s researchers began developing a range of technological solutions, within the context of the Flair Suite™ project.

News in brief

Rock-Eval®: supporting soil research for the climate challenge

One way to decrease the amount of atmospheric CO2 is to reduce greenhouse gas emissions of fossil origin, but it is also possible to increase the quantities of carbon stored in the soil. (...) In the current context of climate change, understanding the evolution of carbon in the ground is critically important. It is for this reason that IFPEN wanted to study the potential offered by Rock-Eval®, a flagship of oil research...

News in brief

Semantic segmentation through deep learning in materials sciences

Semantic segmentation conducted on microscopy images is a processing operation carried out to quantify a material’s porosity and its heterogeneity. It is aimed at classifying every pixel within the image (on the basis of degree of heterogeneity and porosity). However, for some materials (such as aluminas employed for catalysis), it is very difficult or even impossible using a traditional image processing approach, since porosity differences are characterized by small contrasts and complex textural variations. One way of overcoming this obstacle is to tackle semantic segmentation via deep learning, using a convolutional neural network.

News in brief

Digital Rock Physics at IFPEN

Today, characterization of geological reservoirs, a long-standing theme in petroleum exploration, becomes a base of interest for a variety of applications, such as CO2 and hydrogen storage as well as geothermal energy. In recent years, the combined use of 3D microtomography (or micro-CT ) imaging and advanced simulation techniques has allowed the emergence of a digital approach to computing the petrophysical properties of reservoir rocks (Digital Rock Physics). This represents a real complement - and in some cases an alternative - to traditional laboratory measurements.

News in brief

Numerical design based on the analysis of multi-scale porous material microstructures

The design of high-quality porous materials is a major challenge for the energy efficiency of industrial processes in the fields of catalysis and biocatalysis and separation and purification operations. For such applications, these materials derive their properties of interest from their specific microstructure, incorporating a large quantity of empty spaces that are organized and connected on a nanometric scale. IFPEN and Saint Gobain Research Provence (SGRP) joined forces to acquire a tool that will ultimately facilitate the development of porous materials optimized for given usages.

Individual page

Pascal RAYBAUD

Scientific Assistant Director

Researcher in Molecular Modeling applied to Catalysis

Researcher in Molecular Modeling applied to Catalysis

___________________ Open PhD Position in Computational Catalysis for Circular Economy (October 2025 - September 2028) : Molecular s imulations of the mechanisms involved in the recycling of

Individual page

Antoine FECANT

Head of Department

Antoine Fécant holds an engineering degree from the Ecole Normale Supérieure de Chimie de Lille (2004) and a DEA (Master degree) from the University of Lille I the same year. He then obtained a PhD

News in brief

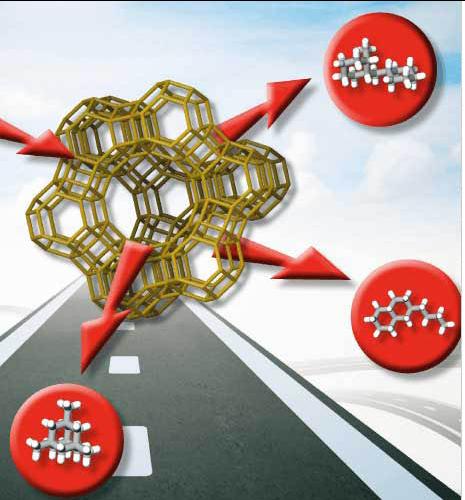

Metal nanoparticles living on the edge

Platinum nanoparticles supported on chlorinated γ-alumina are used in bifunctional heterogeneous catalysts, which are central to numerous industrial processes. An atomic-scale study...

News in brief

Pretreatment and deformulation of biomass-based products

The development of production processes for fuel and platform molecules from lignocellulosic biomass requires knowledge of the chemical composition, on a molecular scale, of the various liquid products generated...

Individual page

Maria-Fernanda ROMERO-SARMIENTO

Research Engineer / Technical Advisor

Organic Geochemistry PhD. HdR.

Sciences of the Earth and the Universe HDR

Organic Geochemistry PhD. HdR.

Sciences of the Earth and the Universe HDR

Maria-Fernanda Romero-Sarmiento joined IFP Energies nouvelles in 2010 as a research scientist in organic geochemistry. She holds a Ph.D. in Organic Geochemistry from the University of Lille (France)