Batteries : from design to recycling

Batteries : from design to recycling

OUR solutions

The solutions proposed by IFPEN concern, firstly, the development and recycling of battery materials and, secondly, the characterization and modeling of battery behavior.

Material conversion and formulation processes

Mineral extraction and refining

IFPEN develops mineral extraction processes based on adsorption, as well as purification and separation techniques, using solvents. The latter technologies also apply to recycled materials.

Battery materials: innovative formulations and processes

IFPEN develops processes for the synthesis of cathode active materials (CAM) as well as their precursors (pCAM) for existing batteries. These processes are developed using pilot production facilities in partnership with IFPEN subsidiary Axens. IFPEN is also interested in new materials for batteries that will emerge from 2035, particularly solid-state batteries. The development of all these new materials is aimed at increasing the mass and volumetric energy density of batteries, improving their safety and durability and limiting the use of critical materials.

This diversified range of innovative, high-performance materials is adapted to existing lithium-ion battery technologies and to new-generation batteries such as solid-state batteries (sulfide and/or polymer-based solid electrolytes) and lithium-sulfur batteries.

Tools dedicated to the formulation of battery materials have been developed for the purposes of exploring new materials. Characterization tools are used to demonstrate the performance of the materials explored.

Points to remember

CAM and pCAM manufacturing processes are developed in partnership with Axens, an IFPEN subsidiary. The two players develop and test their pCAM and CAM manufacturing processes on a pre-industrial scale at the Salindres industrial site in the Gard region of southern France. These innovative, high-performance materials, adapted to existing lithium-ion battery technologies and advanced all-solid-state vehicle batteries, can then be deployed in an industrial facility and released to the French and European markets.

IFPEN also develops battery separators, proposing mineral elements that increase their mechanical and thermal resistance.

Battery material recycling

To recycle battery materials while minimizing the environmental impact, IFPEN is focusing on hydrometallurgical technology.

This technology will be deployed within the framework of a partnership between IFPEN, Axens and Eurecat aimed at building industrial units in France capable of both recycling cathode active materials (CAM) contained in lithium-ion batteries and re-synthesizing them. This ambitious project will help establish French sovereignty in the critical metals and CAM manufacturing sectors.

Points to rememberBattery recycling is an important economic and environmental issue. IFPEN is actively developing processes for battery metal recycling and the re-synthesis of pCAMs and CAMs.

>> To know more about metal recycling and IFPEN's solutions

Battery characterization and tests on several scales, from material to system

IFPEN boasts cutting-edge tools and considerable expertise to study all types of batteries on a range of scales, from the materials used in battery cells (cathodes, anodes, electrolytes, separator), to battery modules/packs for mobility. The data collected are used for the development, calibration and validation of models.

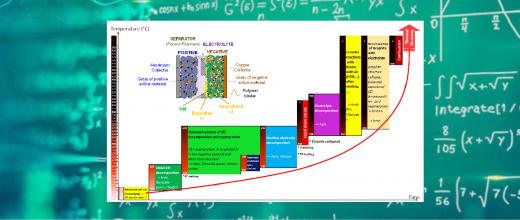

Testing resources such as battery cell, module and pack test benches are thus available to conduct the experiments required to understand electrochemical phenomena and characterize the electrodes and internal components of cells as well as aging phenomena. Imaging tools have also been introduced to enable advanced visualizations and analyze the risk of thermal runaway in cells, for example.

Cell prototyping lines

Cell prototyping lines (in glove boxes) are employed for the preparation of future-generation batteries using innovative battery materials (solid electrolytes, sulfur electrodes) currently being studied and for the characterization of active cathode material performance. The prototypes produced, which can have different formats such as button cell, flexible pouch, cylindrical or even prismatic, are thus prepared and then characterized.

Modeling tools

The models developed by IFPEN are constantly being enhanced and are capable of representing the electrothermal behavior of electrochemical energy storage systems, their aging and even their abuse mechanisms, thanks in particular to the detailed modeling of the thermal runaway phenomenon.

IFPEN keeps its models up to date for the most recent commercial battery and prototype technologies.

For example, IFPEN develops models for sodium-ion batteries that have a lower energy density than lithium-ion batteries but that have a certain number of advantages in terms of availability of the raw material used, a lower environmental impact, safety, etc.

These models are developed in close synergy with experimental research to ensure a high predictive capacity. This strong link between modeling and experimentation is what sets these models apart from other known approaches.

They are used:

- For research conducted by IFPEN to support industry: choice of technology, dimensioning for an application.

- Within the context of collaborative projects to accelerate the development of the electric sector.

- To innovate in areas of current interest such as rapid recharging, the second life of batteries, new generations of solid-state batteries, etc.

Battery simulation software

Knowledge acquired by IFPEN on batteries is collated in the Electric Storage library, which is part of the Simcenter Amesim™ platform. This library, co-developed by IFPEN and Siemens Digital Industries Software, provides users with invaluable assistance when it comes to studying Li-ion battery design, enabling them to carry out:

- pre-dimensioning of the battery pack, thanks to a tool that enables a few macroscopic data to be used to generate a first battery design and its associated model

- automatic calibration of the battery model, on the basis of experimental measurements

- evaluation of complex phenomena, such as aging or thermal runaway.