Mooring lines are essential components for the stability of offshore floating structures, such as those supporting wind turbines. They often consist of steel spiral ropes linked by a chain to the platform (also known as the “floater”). New solutions are currently being studied, in which the rope is directly connected to the floater, thereby removing the need for the chain - which has proved to be a mechanical weak point - and simplifying the connection. But, in such configurations, the rope is subject to a load combined with cyclical tension and bending for which it has not been designed. Spiral ropes have a single-strand1 and are optimized for use under tension only.

Rather than perform representative fatigue tests2, which are expensive and difficult to interpret, IFPEN adopted an approach based on multi-scale numerical simulation. In this approach, detailed modeling of the rope makes it possible to calculate local loads on the metal wires from global loads - tension and bending - at floater level [1, 2]. These calculated loads can then be reproduced in the laboratory on a test bench designed to test numerous applications3.

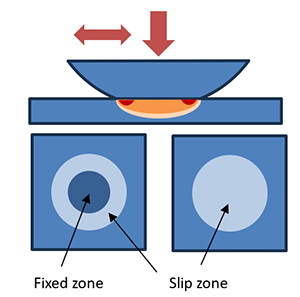

The cyclical tension and bending of the rope are shown to generate fretting fatigue4 in the wires, a phenomenon that is absent with cyclical tension alone, for which friction-induced damage is negligible. In this combined load scenario, the most critical local stress is partial slip, characterized by the fact that the center of the contact remains fixed while its periphery slips (Figure 1).

However, in an offshore anchor cable, the wires are not bare since they are protected from corrosion by a zinc coating5 and grease, in addition to a waterproof polymer sheath around the cable. Fretting fatigue tests helped to elucidate the mechanical effects of these protections. They were conducted for one form of protection only (zinc or grease) or for both.

Taken individually, galvanization and grease have no notable effect [3]. The zinc layer is quickly removed from the contact area by wear and tear, and the grease, which is thick enough not to run down the rope but is quickly removed from the contact area, has limited lubricating power in the event of partial slip.

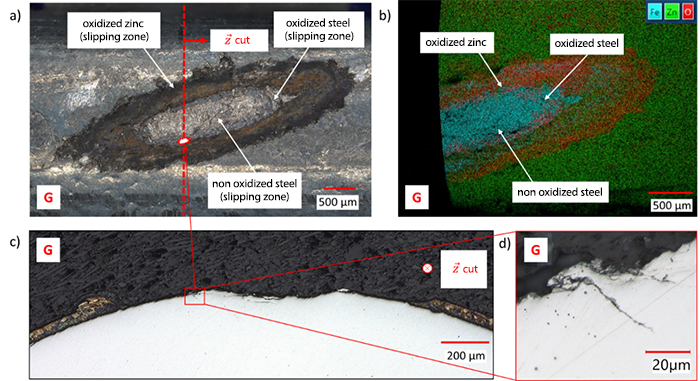

However, the two protections taken together lead to a significant improvement in wire fretting fatigue [4]. The removal of zinc from the contact area (Figure 2) creates a trough that limits the loss of grease and improves its lubricating power, even in the event of partial slip.

a) optical view of trace,

b) EDX view of trace (display of oxygen, zinc and iron),

c, d) optical views of the axial section.

This unexpected synergy is beneficial to the service life of metallic materials exposed to fretting fatigue, as demonstrated by our experimental results (Figure 3).

Combining numerical simulation with mechanical tests representative of local wire loads made it possible to reproduce the mechanisms at play on a small scale, in order to better elucidate them . This understanding of fretting fatigue damage and the favorable synergy between protective elements not designed for this problem opens up new opportunities for improving the design and use of steel anchor cables for floating offshore supports.

1- A strand is an assembly of metal (or textile) wires coiled around a longitudinal axis. A rope may be made up of one or several strands.

2- Reproducing the real full-scale configuration.

3- Located at the Laboratoire de Tribologie et Dynamique des Systèmes (Tribology and System Dynamics Laboratory, Ecole Centrale de Lyon).

4- Phenomenon of crack initiation and propagation due to a combination of fatigue and friction.

5- Galvanic protection.

Thesis by Sébastien Montalvo, Étude de l’endommagement par fretting-fatigue de fils de câbles d’ancrage offshore : influence de la galvanisation, de la graisse et de l’eau de mer (Study of damage induced by fretting fatigue of wires in offshore anchor cables: influence of galvanization, grease and seawater) defended on 8 November 2023.

References:

-

F. Bussolati, M. Guiton, P.-A. Guidault, O. Allix, and P. Wriggers: Lecture Notes in Application and Computational Mechanics, vol. 93 (2019)

-

S. Montalvo, S. Fouvry, M. Martinez, A hybrid analytical-FEM 3D approach including wear effects to simulate fretting fatigue endurance: Application to steel wires in crossed contact, Tribology International 187 (2023) 108713

>> https://doi.org/10.1016/j.triboint.2023.108713

-

S. Montalvo, S. Fouvry, M. Martinez, Effect of zinc coating on the fretting fatigue endurance of crossed steel wires, submitted to Wear in December 2023, submitted to Wear in December 2023

-

S. Montalvo, M. Martinez, S. Fouvry, Effect of zinc coating and grease on the fretting fatigue life of steel wires used in spiral steel ropes, OIPEEC Conference, Lake Garda, Italy, 2024

Scientific contact: michael.martinez@ifpen.fr

You may also be interested in

Optimizing the electric cable of a floating wind turbine

Floating wind turbine technologies, such as those co-developed by SBM and IFPENa , are designed to optimize the recovery of offshore wind energy

Optimizing the electric cable of a floating wind turbine

Floating wind turbine technologies, such as those co-developed by SBM and IFPENa , are designed to optimize the recovery of offshore wind energy