Processes using heterogeneous catalysis1 require the design and development of innovative materials, with controlled mechanical and textural properties, to produce effective catalyst supports. The porous microstructure of these supports has a significant impact on the performance of the supported catalyst, since it strongly affects the support’s mechanical resistance and transport phenomena. The industrial manufacture of alumina extrudates is conducted using a kneading-extrusion process, aimed at converting a powdered alumina precursor (boehmite) into micrometric solids.

This preparation process makes it possible to optimize the support’s properties of interest by adjusting the conditions of each of the two individual operations.

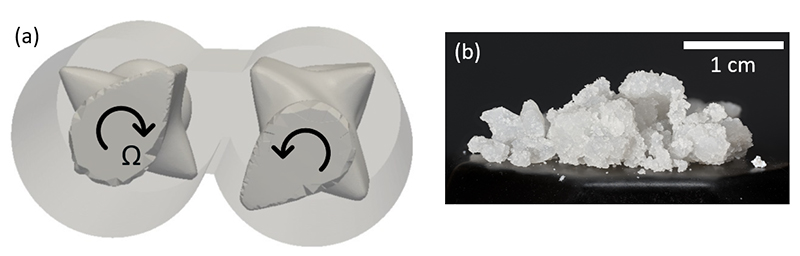

An experimental study conducted as part of ongoing PhD research2 related exclusively to the kneading operation, with a view to characterizing its effects on the properties of boehmite pastes [1, 2]. To do this, several pastes were prepared in a pilot mixer (illustrated in Figure 1), mixing boehmite powder and acidic and basic aqueous solutions. The textural and mechanical properties of the pastes obtained were studied as a function of kneading time (from 3 min to 4 h), blade rotation speed (from 10 to 100 rpm) and paste composition (resulting pH between 5 and 9, modified by the addition of different concentrations of basic solutions). The distribution of pore sizes, the specific surface area and pore volume were analyzed via nitrogen physisorption and mercury porosimetry on dry samples, while the mechanical properties were characterized in situ in the mixer by measurement of the mixing torque.

(b) Photo of a boehmite paste with pH = 6.2, taken outside the mixer.

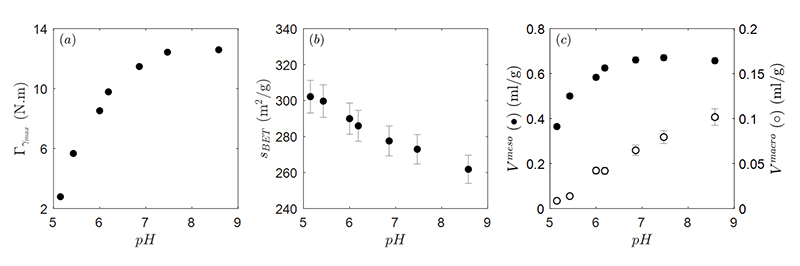

The results obtained demonstrate that the paste composition had a significant effect on sample properties. For example, an increase in the torque measured in the mixer was observed, as well as in the porosity of the dried paste (Figure 2), for compositions with a higher pH. Moreover, the evolution over time of the torque as well as of the textural properties of the paste are governed by the cumulative deformation, a quantity calculated as the product of rotation speed and mixing time and homogeneous to the number of revolutions undergone by the paste. Lastly, it turns out that a relevant parameter to rationalize the evolution of these textural properties - as measured for a broad range of pH values, mixing times and rotation speeds - is the product of this cumulative deformation by paste pH.

This study, dedicated to the characterization of the effects of kneading on the textural and mechanical properties of boehmite pastes, made it possible to separately identify the acidic-basic influence of their composition and the mechanical contribution of the mixer. Identifying a unique control parameter (product of paste deformation and pH) will make it possible, in the laboratory, to determine exactly what operating conditions should be applied at the mixing stage to manufacture a paste with a specific porosity. Consequently, this result is of interest for the development of new innovative heterogeneous catalysts. Finally, the next stage of this research will involve ex situ determination of the mechanical properties of pastes, using techniques such as rheometric analysis, indentation and compression, in order to obtain a more rigorous characterization of the effect of kneading on the mechanical properties of boehmite pastes.

1- Such as hydrotreatment and catalytic reforming processes.

2- Thesis by Mathilde Auxois, Identification et étude de descripteurs du malaxage d’une pâte de boehmite pour la conception de nouveaux solides. (Identification and study of boehmite paste kneading descriptors for the design of new solids)

References:

-

Mathilde Auxois, Marine Minière, Chloé Bertrand-Drira, Fabien Salvatori, Jan Verstraete, Sébastien Manneville, Thibaut Divoux, Tuning properties of catalysts supports via kneading conditions of colloidal pastes, European Colloid and Interface Society congres, 2023

-

Mathilde Auxois, Marine Minière, Chloé Bertrand-Drira, Fabien Salvatori, Jan Verstraete, Sébastien Manneville, Thibaut Divoux, Textural properties of dense granular pastes produced by kneading, arXiv:2402.09220

Scientific contacts: mathilde.auxois@ifpen.fr and marine.miniere@ifpen.fr

You may also be interested in

CARMEN JRL: a breakthrough research for the energy transition

Boehmite rhapsody! Controlled precipitation

Transition aluminasa, widely used as catalyst supports, play a key role in numerous refining processes.

Boehmite rhapsody! Controlled precipitation

Transition aluminasa, widely used as catalyst supports, play a key role in numerous refining processes.