Biofuels are one of the components of the transition to renewable energies, and their use is an effective way of decarbonizing transport. However, they are produced from feedstocks whose composition can affect the steel equipment used for their conversion. For example, the hydrotreatment of vegetable oils and animal fats leads to the exposure to high concentrations of oxygenated compounds, naturally present in the initial feedstock or resulting from their conversion, which can react with metallic materials. The potential presence of high concentrations of free fatty acids is another factor providing the risks of corrosion.

A PhD study was dedicated to the study of this phenomenon liable to affect the reliability of installations1. The research employed corrosion experiments in conditions representative of the process: pressure (up to 80 bar in the presence of hydrogen) and temperature (up to 350°C), with frequent renewal of the corrosve media without opening the autoclave2. After exposure tests, analyses conducted on the materials and feedstock made it possible to quantify the corrosion and understand its mechanisms.

Some significant results emerged for different grades of steel:

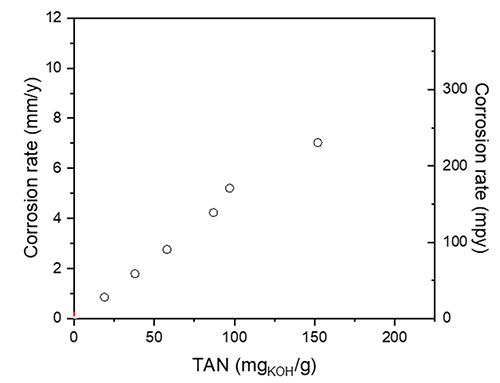

- at 220°C, generalized corrosion rates of more than 1 mm/year were observed on carbon and low alloy steels with highly acidic feedstocks (TAN > 16)3;

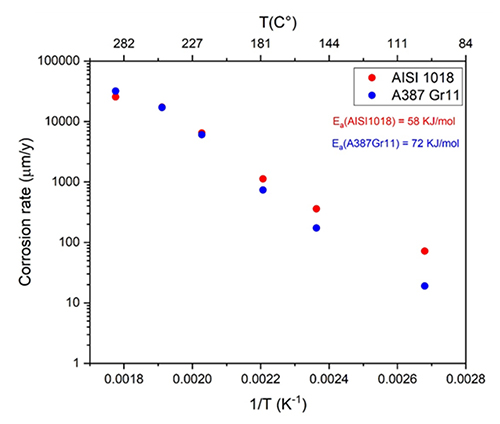

- in a range between 100 and 290°C, the corrosion kinetics of carbon and low alloy steels follow an Arrhenius-equation-type relationship (Figure 1) and evolve linearly with respect to the TAN (Figure 2);

- in fatty acid distillates (TAN=200), the risk of corrosion requires the use of stainless grades alloyed with molybdenum, such as 316L or 317L.

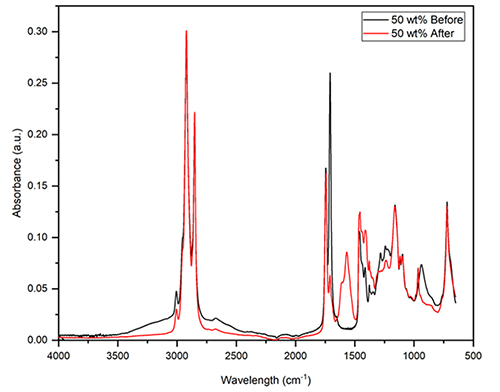

The corrosion mechanism was identified through the use of several complementary analysis techniques (potentiometric titration, infrared spectroscopy, simulated distillation). The consumption of free fatty acids with a ratio of 2 moles of acid for 1 mole of dissolved iron is highlighted by the reduction in the characteristic absorption band of the vibration band of the C=O bond at 1711 cm-1, characteristic of oleic acid (Figure 3). In addition, a new IR absorption cluster is observed in the 1567 – 1605 cm-1 region, characteristic of the vibrations of the carboxylate function involved in the formation of organometallic complexes. These results prove that steel corrosion in these environments is promoted by the formation of complexes [1-2].

The methods and knowledge developed during this PhD research are now being used for numerous industrial biomass conversion process developments, as well as for co-processing operations5. For the design of new industrial units, safer construction materials can now be chosen, and for revamp of existing units, they provide tools for defining the limits of use of the most corrosive feedstocks.

1- [1] Thesis by F. Andari, Impact of biomass composition on corrosion: case of the hydrotreatment of vegetable oils and waste oils to produce biofuels, PhD thesis, Lyon 1 University, 2022.

2- Partial renewal of feedstock in semi-batch mode, without opening the test reactor or temperature reduction.

3- The TAN (Total Acid Number) is a measurement of the total acidity of an oil, expressed in milligrams of potassium hydroxide required to neutralize one gram of oil (mg KOH/g oil).

4- Distilled Tall Oil

5- Treatment of a feedstock made up of a mixture of conventional hydrocarbons and an alternative resource (bio-based oil, pyrolyzed plastic waste, etc.)

References:

- Andari, J. Kittel, J. Fernandes, N. Godin, B. Ter-Ovanessian, F. Ropital, High temperature corrosion in various grades of vegetable and waste oils used for bio-fuel production, Corrosion Science, 2022, Vol 206, Article 110501

>> https://doi.org/10.1016/j.corsci.2022.110501

- F. Andari, J. Kittel, J. Fernandes, L. Dodelin, F. Ropital, Corrosion issues in the conversion of vegetable and waste oils to produce biofuels, NACE/AMPP 2023 Conference paper 19308

>> https://onepetro.org/amppcorr/proceedings-abstract/AMPP23/All-AMPP23/AMPP-2023-19308/527014

Scientific contacts: Jean Kittel, joanna.fernandes@ifpen.fr and François Ropital

You may also be interested in

Self-repair against localized corrosion

Due to their low cost and their good mechanical properties, carbon steels are a widely used material, including for equipments in contact with harsh environments, such as aqueous media containing CO2...