Driven by the quest for innovative transport technologies, IFPEN has spent many years developing and helping to market new biofuel production processes (Vegan®, Futurol®, BioTfueL®). Among the various process options studied, the bioethanol production chain based on lignocellulosic resources offers numerous advantages, particularly in terms of resource availability and operating conditions for their conversion, which are gentle compared with a thermochemical process.

Bioethanol production consists of three key conversion steps: pre-treatment of lignocellulosic biomass, enzymatic hydrolysis of cellulose and fermentation of the sugars obtaineda. The main role of enzymatic hydrolysis is to depolymerize cellulose into glucose, and to do so it uses a mixture of specialized enzymes (endoglucanases, cellobiohydrolases, β-glucosidases, etc.) that act in synergy to catalyze the reaction.

The characteristic duration of this hydrolysis is several days, which is a long time compared to the pre-treatment and fermentation steps, and reducing this duration would go a long way towards improving the economic viability of the overall process. Notable progress has been made in recent years in terms of understanding the reaction mechanisms [1] but without shedding light on the deactivation phenomena that affect the enzymatic hydrolysis reaction by significantly reducing enzyme activity (by 50% every 24 hours). Among the phenomena considered, the loss of activity at the air-liquid interface through enzyme denaturation, the loss of activity through adsorption on the inert lignin surfaces and the loss of activity by non-productive adsorption on the cellulosic surfaces (enzymes blocked on the cellulose and no longer acting) was studied within the context of PhD researchb.

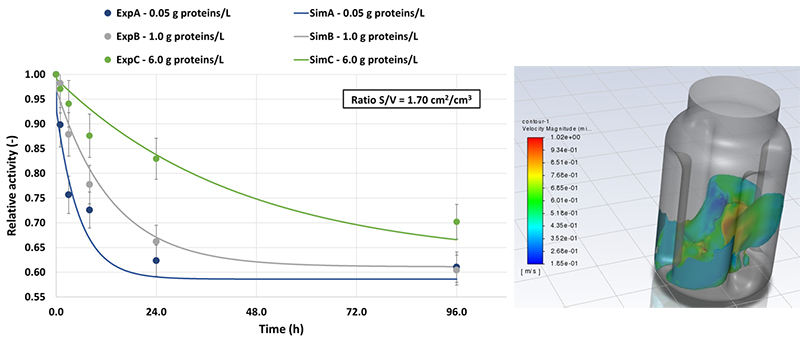

The experimental study of the loss of activity in the presence of contact with air revealed that the phenomenon was extremely marked for high Surface/Volume ratios (air-liquid surface to solution volume ranging from 0.3 to 1.7 cm2/cm3) and could lead to activity losses of up to 40% (figure 1 - left). It was then followed up with a kinetic modeling approach to predict activity losses associated with this particular phenomenon [2]. Since the model required knowledge of the air-liquid surfaces produced by agitation, these were determined using CFD numerical simulationc (figure 1 - right).

Concerning activity losses associated with enzyme adsorption on different lignocellulosic biomass surfaces, other research conducted during the PhD thesis made it possible to evaluate the distribution of enzymes adsorbed on the cellulose and lignin surfaces during enzymatic hydrolysis. Since enzymes adsorbed on lignin play no role in the reaction, this study showed, from adsorption isotherm calculations, that enzyme activity losses associated with adsorption on lignin may represent up to 25% of initial activity (publication pending).

All of these results will be combined with mechanistic models already available at IFPEN [1] to improve the prediction of enzymatic hydrolysis performances, optimize reaction time and reduce reactor volumes.

a- Glucose, xylose, galactose, arabinose, mannose.

b- Thesis by Laura Cachafeiro, “Hydrolyse enzymatique de la biomasse lignocellulosique : étude de l'adsorption et de la désactivation des cellulases“ (Enzymatic hydrolysis of lignocellulosic biomass: cellulase adsorption and deactivation study), Lyon 1 University, 2023 (supervised by D. Hudebine - IFPEN).

c- Computational Fluid Dynamics.

References:

-

M. Huron, D. Hudebine, N. Lopes Ferreira, D. Lachenal, Mechanistic modeling of enzymatic hydrolysis of cellulose integrating substrate morphology and cocktail composition, Biotechnology and Bioengineering, 113(5), pp. 1011-1023, 2016.

>> DOI: 10.1002/bit.25873

-

[2] L. Cachafeiro, S. Heiss-Blanquet, D. Hudebine, An experimental and modeling approach to describe the deactivation of cellulases at the air–liquid interface, Biotechnology and Bioengineering, Early Access, 2024.

>> DOI: 10.1002/bit.28698

Scientific contact: Damien Hudebine