| The life cycle of hydrotreatment catalysts: |

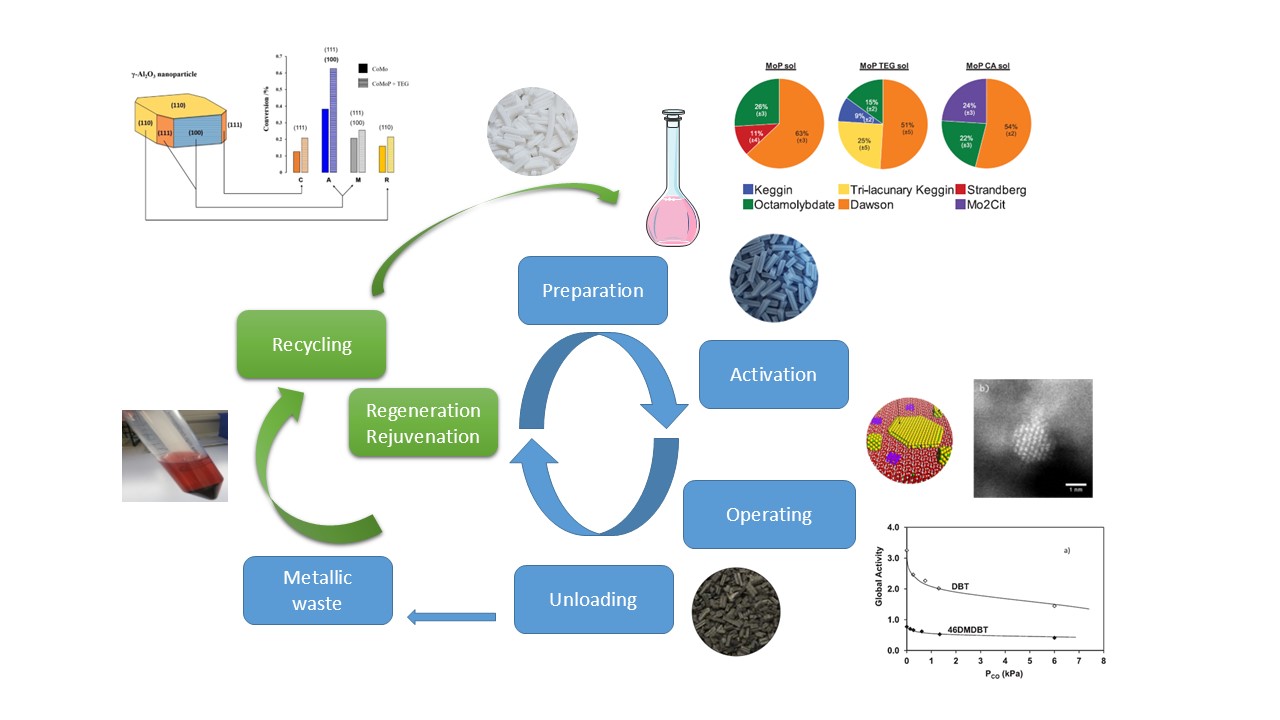

Catalysts are essential products for numerous industrial processes, including the hydrotreatment of oil feeds or bio-based feeds. Their properties stem from the active metal materials they contain, the value and criticality1 of which justify efforts to recover them from waste products. Accordingly, as a major producer of catalysts, one of IFPEN ’s key priorities is to apply the principles of the circular economy to them. To improve their recycling, it is essential to have a thorough understanding of the life cycle of these catalysts - made up of transition metal sulfides on a porous alumina-type oxide (figure 1) - and this was the focus of my national accreditation to direct research (HDR).

The results presented summarize research conducted within the framework of some ten PhD theses and post-doctoral projects that I supervised in partnership with academic laboratories. From a fundamental point of view, this research was aimed at acquiring a better understanding of the link between the genesis of these materials and their catalytic performances, drawing on innovative synthesis and advanced characterization methods (ASAXS2, in-situ XAS3).

1 The majority can be found on the European Union’s list of critical metals

2 Anomalous Small-Angle X-Ray Scattering

3 X-ray Absorption Spectroscopy

For example, with regard to the effect of the support (alumina, titanium oxide and silica), groundbreaking results were obtained concerning the influence of the crystallographic nature of alumina, leading to the proposal of an original approach in the field of surface science. Thus, the effects of alumina face orientation on interactions with the active phase, the rate of sulfidation, the promotion ratio of MoS2 by Co and ultimately on HDS performance4 were demonstrated as a function of the presence of a dopant, such as phosphorus and/or organic additives [1].

The study of the catalyst activation stage revealed differences in the sulfidation mechanism depending on whether it is carried out in the gas phase, as is standard practice in laboratories, or in the liquid phase, as is the case in the refinery setting. In addition, a novel combination of Raman spectroscopy and XAS enabled the first ever speciation of molybdenum-based substances, firstly in an aqueous solution, and secondly supported on an alumina surface. This paves the way for new insights into catalyst oxide precursors and their link with catalytic performance [2].

Lastly, the operational function of catalysts was studied, with a specific focus on the impact of inhibitors on their deactivation and regeneration. The inhibitors chosen for this were the oxygenated compounds H2O and CO, particularly representative as by-products of the oxygenated substances contained in large quantities in the new biomass-derived streams now entering refineries in the context of co-processing [3]. This research highlighted the challenges of meeting refined product specifications while coping with increasingly heterogeneous feedstocks, in particular the search for new, more efficient and resistant catalysts.

The solid foundation of knowledge resulting from this research can be used to generate proposals for future catalyst recycling strategies and processes.

4 Hydrodesulfurization

References :

- R. Garcia de Castro, E. Devers, M. Digne, A.-F. Lamic-Humblot, G. D. Pirngruber, X. Carrier, ChemCatChem (2022) e202101493, Role of Phosphorus and Triethylene Glycol Incorporation on the Activity of Model Alumina-Supported CoMoS Hydrotreating Catalysts,

>> doi.org/10.1002/cctc.202101493

- C. Lesage, E. Devers, C. Legens, O. Roudenko, O. Delpoux, A. Beauvois, T. Putaud, V. Briois, ChemCatChem 2024, 0, e202401403, Speciation of the Oxide Phase of Molybdenum-Based HDS Catalysts Enhanced with Organic Additives Using an EXAFS/Raman Coupling Methodology,

>> doi.org/10.1002/cctc.202401403

- F. Pelardy, A. Daudin, E. Devers, C. Dupont, P. Raybaud, S. Brunet, Applied Catalysis B: Environmental 183 (2016) 317–327, Deep HDS of FCC gasoline over alumina supported CoMoS catalyst: Inhibiting effects of carbon monoxide and water,

>> dx.doi.org/10.1016/j.apcatb.2015.10.026F

To contact : Elodie Devers