27.02.2025

6 minutes of reading

To meet the challenges of climate change, the transition to renewable energies and the decarbonization of transport are essential, with electric mobility and lithium-ion batteries playing a central role. Battery aging is a complex phenomenon, driven by numerous factors, and requires robust models to predict and optimize their use. Quentin Mayemba’s PhD research resulted in the development of an innovative general machine learning model capable of adapting to various datasets to predict battery aging. These contributions, which are invaluable to the scientific community, provide robust tools and open up new avenues for the development of methodologies tailored to the study of lithium-ion batteries.

Background: improving battery reliability

Against a background of climate change, carbon impact reduction has become a global priority, making the transition to renewable energy sources and the decarbonization of key sectors, such as transport, essential. In this context, electric mobility plays a pivotal role by offering a sustainable alternative to traditional IC vehicles. As core components of electric vehicles, lithium-ion batteries are central to this energy revolution. Their performance, life-span and reliability are crucial to the success of electric mobility and, by extension, to the attainment of CO2 emission reduction targets. It is therefore vital to understand and be able to predict the aging of batteries in order to optimize their performance. This involves numerical simulation, using software such as Amesim (developed by Siemens), which can reproduce and analyze the thermal, electrical and mechanical behavior of batteries, making it a powerful tool for improving their design and management.

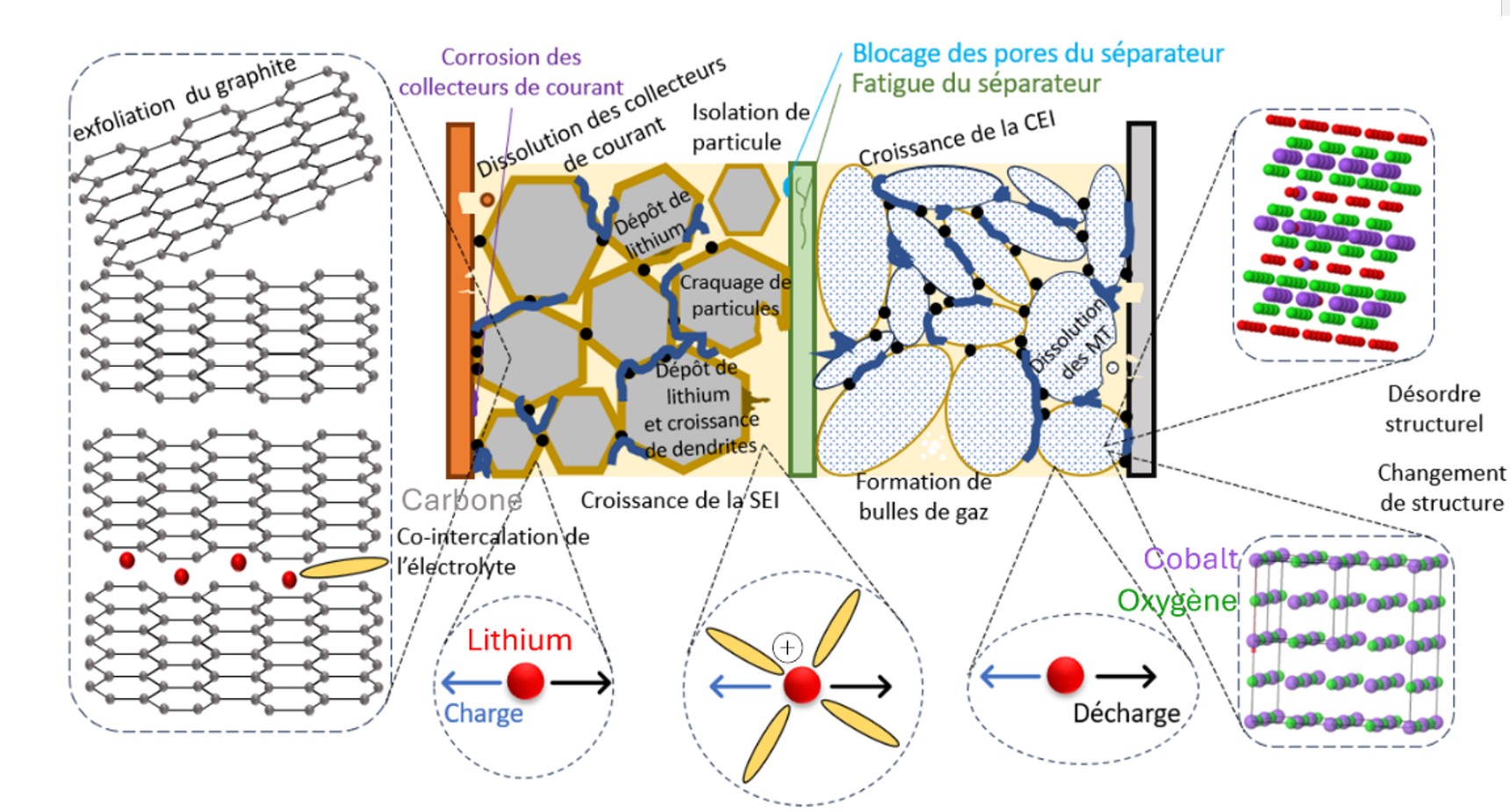

However, the aging of lithium-ion batteries is a complex phenomenon, influenced by multiple factors, such as temperature, charge and discharge cycles, state of charge, etc. Inside the cells, chemical and mechanical reactions take place, leading to a progressive loss of capacity and an increase in internal resistance. These interdependent mechanisms vary considerably depending on battery chemistry (for example NMC1 or LFP2, etc.) and use conditions.

For example, lithium deposits (Fig. 1) can form on the negative electrode, restricting the movement of lithium ions, and reducing useable energy , while positive electrode degradation can alter the structure of the active material. Given the complexity of these phenomena, the need to develop a model that was both generic and versatile, capable of covering the full range of potential processes, was apparent.

1 Nickel Manganese Cobalt

2 Lithium ferrophosphate

3 Commonly referred to as “cycle capacity”

In this context, Quentin Mayemba's PhD research [1], carried out in collaboration with Siemens and the Ampère laboratory at INSA Lyon, led to the development of a generic algorithm, based on artificial intelligence, capable of adapting to any type of cell and to their different aging mechanisms. The primary objective of this work is to create prognostic tools for battery aging, with the aim of integrating them into system simulation software. The two publications associated with the research explore battery aging data and compare conventional approaches with the use of artificial intelligence (machine learning).

The four phases of the PhD research

The PhD research conducted by Quentin Mayemba was divided into four key steps:

1. Benchmarking of machine learning algorithms: Among the algorithms identified in the literature review and then tested, including SVM4, KNN5, decision trees6 and neural networks7, the XGBoost8 model proved to be the best performing overall, but demonstrated limitations in terms of the reproducibility of its predictions over the whole range of aging conditions. Subsequently, neural networks were favored for their ability to adapt to any type of database.

2. Database analysis [2] : A comprehensive review of the literature identified some thirty relevant databases on battery aging, covering a wide range of chemistries and operating conditions. Their detailed analysis, taking into account the diversity of chemistries and operating parameters (temperature, state of charge - SOC, charge and discharge currents) made it possible to assess the specific features and limitations of each dataset, with a view to harnessing their potential for aging modelling. Once this process had been completed, three databases were deemed particularly suitable for further investigation, due to their quality, wealth of information and compatibility with the research objectives.

3. Development and application of machine learning tools [3]: Based on data analysis, machine learning algorithms were developed and applied to predict the state of health of batteries. These tools include “simple” neural networks and other advanced models capable of detecting long-term trends. The performance of these algorithms was evaluated on the different databases, with a view to comparing their efficiency with traditional empirical models.

4. 4. Model hybridization: Alongside the PhD research, an internship focused on the hybridization of empirical models and machine learning, with the outputs of empirical models used as inputs for neural networks. The results show that hybridization can improve performances provided the empirical models are of sufficiently high quality. If not, they can disrupt learning, underlining the importance of reliable, relevant data and the central role of variable selection.

4 Support vector machines: supervised machine learning algorithms for outlier detection, regression and classification

5 k-nearest neighbors method for supervised learning

6 Tree organizing choices as a function of thresholds optimizing separation

7 Learning method inspired by the workings of the human brain

8 Supervised model based on decision trees corrected by successive weightings.

Benefits and specific features of the algorithm construction method

The method used is based on “life slices” defined according to established industry thresholds, with the aim of segmenting the life cycle of a battery into different periods. Each of these is characterized by unique operating parameters, such as temperature and SOC9, as well as charging and discharging currents. By analyzing these slices separately, it becomes possible to identify critical phases where aging accelerates or changes in nature.

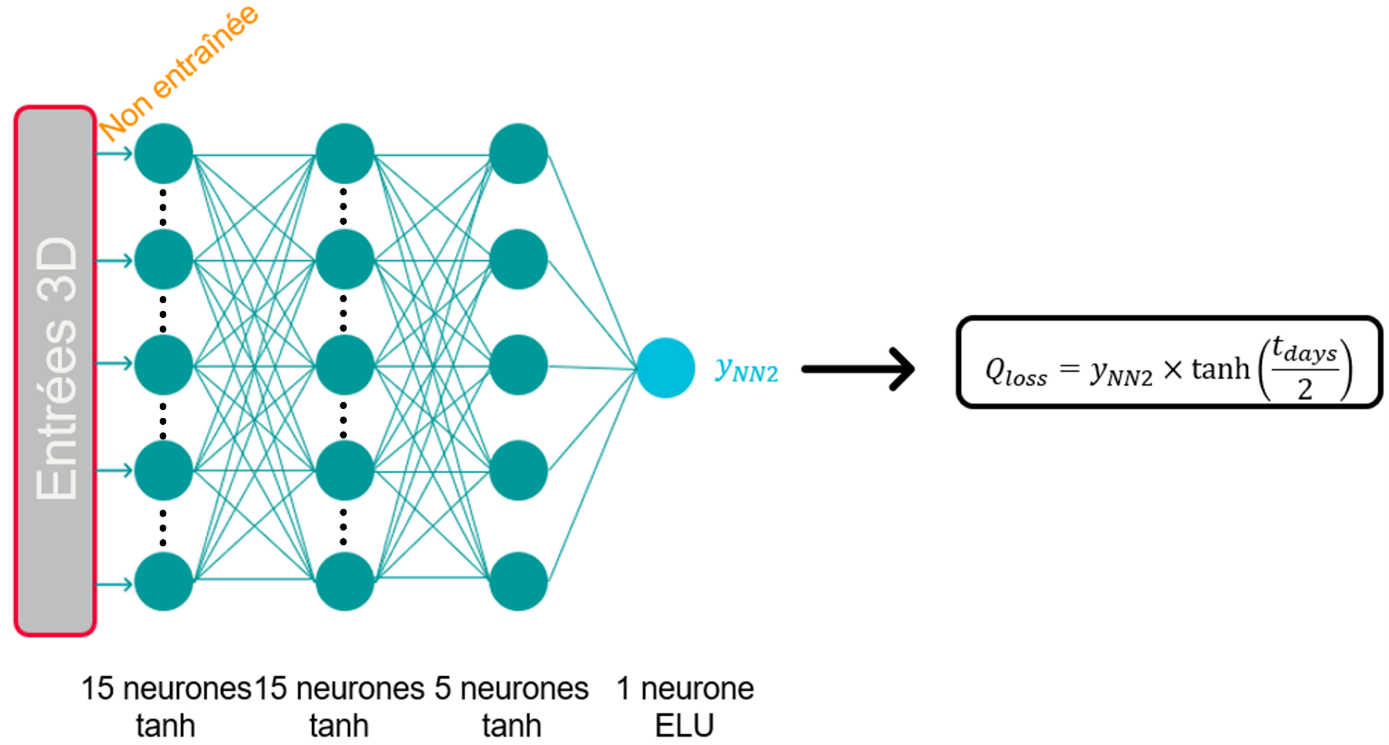

This approach facilitates the use of available data, even when there are gaps in the data or the data are derived from a variety of characterization protocols. In addition, it allows long-term trends to be taken into account in modeling. Neural networks (Figure 2) trained on these slices are better equipped to generalize results, ensuring greater accuracy.

9 State of Charge

Key results and prospects

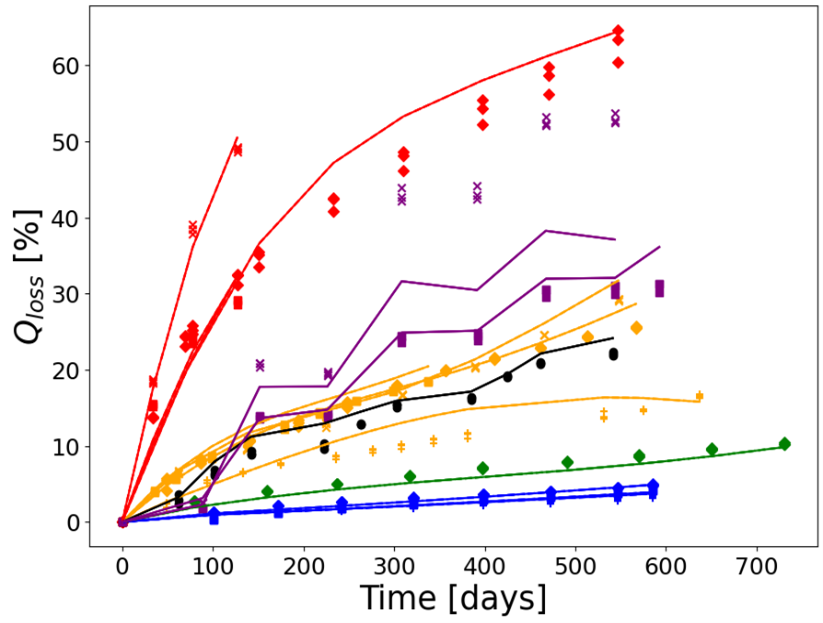

The algorithms developed using three different databases demonstrated an increased ability to predict battery capacity loss compared with the algorithms in the literature (figure 3). These bases included distinct cycling profiles, such as fast charging and stationary use, as well as diversified environmental conditions. In particular, neural networks made it possible to detect complex phenomena and long-term trends through life-slice analysis. The results obtained were significantly more accurate than those derived from conventional empirical models, with a root mean square error reduced to less than 3%. Overall, the models developed are about twice as powerful as conventional approaches in terms of accuracy.

.

When integrated into system simulation software, these models can help optimize battery management and maintenance strategies, enhancing operational and extending battery lifespan. These advances have concrete applications in a wide range of fields, from electric mobility to stationary storage, where better prediction of aging enables more efficient maintenance planning and reduced operating costs.

This multi-disciplinary collaborative research has led to the creation of hybrid models, combining classical models and machine learning, which represent a major step forward for the optimal use of batteries and for the future of the applications they are used in.

In terms of future prospects, the models could be improved by automating and optimizing the selection of thresholds for battery life slices. In addition, the development of Explainable Artificial Intelligence (XAI)10 tools would enhance transparency and their industrial adoption. Finally, the models developed could be enhanced to predict specific aging mechanisms, such as loss of active mass, loss of cyclable lithium and changes in internal resistance. All these developments will help to refine our understanding of battery aging and maximize battery efficiency in a wide range of applications.

10 AI systems that take decisions and explain how and why these decisions were taken

References :

[1] Thesis by Q. Mayemba, Développement d’algorithmes d’intelligence artificielle pour estimer l’état de santé des batteries lithium-ion, [The development of artificial intelligence algorithms to estimate the state of health of lithium-ion batteries], defended on 13/01/2025 at Lyon University

[2] Mayemba, Q., Ducret, G., Li, A., Mingant, R., & Venet, P. (2024a). "General Machine Learning Approaches for Lithium-Ion Battery Capacity Fade Compared to Empirical Models." Batteries, 10(10), 367.

>> https://doi.org/10.3390/batteries10100367

[3] Mayemba, Q., Mingant, R., Li, A., Ducret, G., & Venet, P. (2024b). "Aging datasets of commercial lithium-ion batteries: A review." Journal of Energy Storage, 83, 110560.

>> https://doi.org/10.1016/j.est.2024.110560

Scientific contacts: Gabriel Ducret, Rémy Mingant