05.02.2025

5 minutes of reading

E-fuels: challenges and opportunities

Focus n°3

Towards a first value chain for the production of e-fuels

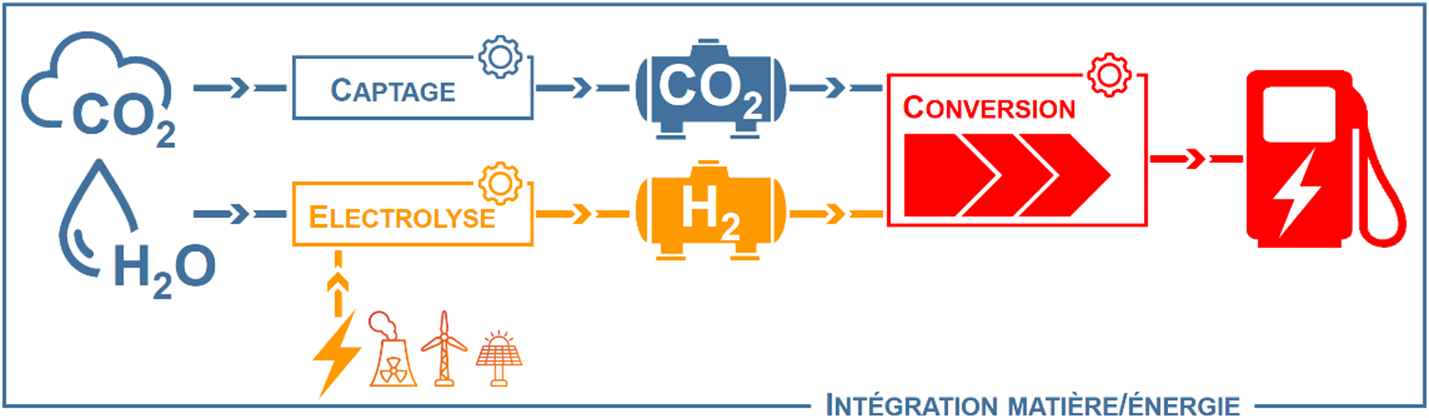

Several pathways for the production of e-fuels are currently under study, at various levels of maturity. The pathway based on CO2 conversion with hydrogen, also known as Power-to-X, is the most mature to date and will be the first value chain for the industrial production of synthetic fuels. It must be deployed by 2030 to meet regulations targets for long distance transport (see Focus #1). It relies on three essential components: i) CO2 capture, ii) hydrogen production from low-carbon electricity, and iii) CO2 conversion into fuel(s). These components must be integrated efficiently to minimize investments, production costs and optimize energy and material yields, based on Life Cycle Assessment (LCA) analyses.

Regarding the capture of CO2, the initial and most mature technologies aim at capturing concentrated CO2 sources from industrial emissions of fossil or biogenic origin (concentration typically ranging from 6% to 30%). These technologies will have to be revisited and enhanced to enable the capture of atmospheric CO2 (concentration around 400 ppm, or 0.04%) through Direct Air Capture (DAC) processes, as beyond 2040, in Europe, regulations mandate the exclusive use of biogenic or atmospheric CO2 to produce synthetic fuels.

Hydrogen production is defossilized by using electrolysis with renewable or nuclear electricity. Alkaline electrolysis is currently a widely used technology, with efficiencies ranging from 60 to 70%, but it is not well-suited for the intermittency of renewable energies. Proton Exchange Membrane (PEM) electrolysis and High Temperature Electrolysis (HTE) technologies, which are more suitable for electrical intermittency, are undergoing intensive research and innovation to improve efficiencies (HTE achieving >80%).

The conversion of CO2 and hydrogen into fuels consists of several steps, including:

• A first step converting CO2 into CO, for example, through a reaction like RWGS (Reverse Water-Gas Shift), currently needing validation at an industrial scale, or through a co-electrolysis reaction (still to be matured),

• A second step converting CO in presence of H2 into fuels, either through the Fischer-Tropsch process or through the methanol pathway, both technologies being industrially mature.

The less mature components need to undergo significant research and innovation efforts to scale up to an industrial level. The challenge also lies in integrating all components, including the mature ones, to form a complete, functional, and efficient value chain. Each component therefore needs to be developed and optimized within a systemic approach, including LCA analysis, to maximize energy and material efficiencies and minimize costs. For instance, one can mention the possibility of recovering the heat emitted by the Fischer-Tropsch synthesis to power an HTE or DAC system. The overall targeted efficiency of the complete chain is around 50 to 55%, to be compared with that of electrolytic H2, ranging from 60 to >80% depending on the technologies.

The entire chain, including its components and integration, is covered by the expertise of IFPEN and CEA R&I teams, including techno-economic studies and multi-criteria LCA. Other synthesis pathways are also under R&D, such as electrocatalysis and photoelectrocatalysis, biological pathways, and hybrid technologies.

E-fuels: challenges and opportunities - Glossary

ADEME: French energy transition agency (www.ademe.fr)

ANCRE: French National Alliance of Coordination of Research for Energy

CBAM: Carbon Border Adjustment Mechanism